Increasing production to become more profitable is the goal of every manufacturer and companies rely upon an advanced manufacturing engineer to achieve that goal.

When buying school supplies, clothing, or even a new car, people don’t often think about how those things were designed, the machines used to manufacture them, or how much it cost to produce them. An advanced manufacturing engineer assumes those duties and responsibilities to make sure that the goods manufactured are of good quality, that adequate supplies are available, and that production costs are controlled to allow their employer to profit from the sales.

Job Description:

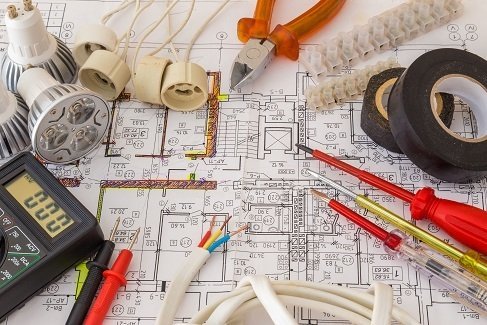

An advanced manufacturing engineer generally works to create the design and function of items such as equipment, tools, computers, and even robots, to allow the company they work for to increase production of products that are manufactured efficiently of high quality materials, but at a reasonable cost to allow the company to be competitive with other companies in the industry. Advanced manufacturing engineers may work at many different types of companies who manufacture a wide range of products such as chemicals, computers, or airplanes. Specific jobs done by an advanced manufacturing engineer are:

An advanced manufacturing engineer generally works to create the design and function of items such as equipment, tools, computers, and even robots, to allow the company they work for to increase production of products that are manufactured efficiently of high quality materials, but at a reasonable cost to allow the company to be competitive with other companies in the industry. Advanced manufacturing engineers may work at many different types of companies who manufacture a wide range of products such as chemicals, computers, or airplanes. Specific jobs done by an advanced manufacturing engineer are:

— Create quality standards and make sure the company attains them

— Set up and manage both manufacturing equipment and procedures

— Test efficiency of manufacturing operation

— Create budgets for operation based on labor, production time, resources required, and deadlines to be met

— Work with managers and production team to oversee progress and success

— Investigate manufacturing software to improve production

STEM Type:

STEM Type:

Solver

Median Salary:

The median salary earned by an advanced manufacturing engineer is $71,879. Work schedules are typically five days per week, but can vary according to the type of industry and deadlines faced by the manufacturer.

Education Required:

The advanced manufacturing engineer must earn a bachelor’s degree in mechanical engineering. In addition to a college degree, job candidates are expected to be good at math and problem-solving, but also skilled in communication and creative in approaching designs and solutions to production issues. Internships are often required when first hired by a manufacturer. A master’s degree in a related area can lead to advancement in the field.

How to Prepare:

High school students interested in a career as an advanced manufacturing engineer should take courses in math, calculus, economics, and technology.

A career in advanced manufacturing engineering rewards employees with the opportunity to be creative and use their skills to allow a company to improve and succeed. The challenge to increase productivity and decrease costs simultaneously is one that a good advanced manufacturing engineer can tackle and overcome, all in a day’s work.

Want to learn more about the changing and surprisingly advanced field of manufacturing? Check out these five top STEM manufacturing careers or getting involved in a Manufacturing Day event near you!

Leave A Comment

You must be logged in to post a comment.